It's a clamshell box! with filler!

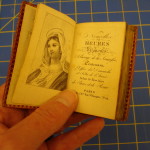

This blog explains how we construct an acid-free enclosure to protect a book that is too small to stand alone on a shelf. The dimensions of the book in question are approximately 2” X 3”. As a rule University of Cincinnati Libraries requires that all shelved items be at least 5” X 7”.

Normally when we make a clamshell box, it is custom made to the exact size of the book that will rest inside it. If the box is constructed too tightly, it could damage the book when the cover is closed. If the box is made too loosely, it will rattle around inside and again could be damaged.

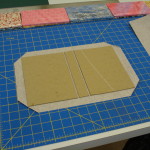

In this case we will build the box around the filler that the small book will fit into. I’ll measure and cut several layers of foam board and glue them together to the exact thickness of the small book. The outer dimensions are 5”X 7”. Next I’ll measure and cut a notch into the center of the filler with our scalpel. I will cut this slightly larger than the small book. The opening is made slightly larger to accommodate the cloth that will cover the filler as well as a thin strip of soft felt. After the filler section has been constructed and sanded smooth, a paper diagram is drawn to map out the best way to cover the filler block with cloth.

In this case we will build the box around the filler that the small book will fit into. I’ll measure and cut several layers of foam board and glue them together to the exact thickness of the small book. The outer dimensions are 5”X 7”. Next I’ll measure and cut a notch into the center of the filler with our scalpel. I will cut this slightly larger than the small book. The opening is made slightly larger to accommodate the cloth that will cover the filler as well as a thin strip of soft felt. After the filler section has been constructed and sanded smooth, a paper diagram is drawn to map out the best way to cover the filler block with cloth.

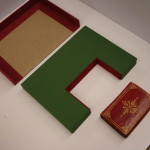

At this point I chose the fabric and paper for the box, filler and pastedowns. Since the book is red leather with olive endpapers and paste downs, I tried to match those colors with the material I would use in the construction of the clamshell box. Because the clamshell would not be large, I chose cloth over the thicker, heavier Buckram fabric. After covering the filler block with green cloth, I am ready to begin the construction of the actual clamshell box.

I chose “70” wei ght board for the box. The box will consist of two three-sided trays and a cover case. We begin by making the smaller, bottom tray first. The second tray will be built around the first. I squared the edges of the “70” wt. board and butted the edges of the board up against the right angle walls of our box template. Next I put the filler block on top of the board and, using specially made height, width and thickness jigs, I marked the two places where I would cut the piece on our board shears.

ght board for the box. The box will consist of two three-sided trays and a cover case. We begin by making the smaller, bottom tray first. The second tray will be built around the first. I squared the edges of the “70” wt. board and butted the edges of the board up against the right angle walls of our box template. Next I put the filler block on top of the board and, using specially made height, width and thickness jigs, I marked the two places where I would cut the piece on our board shears.

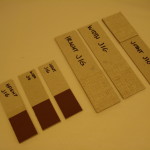

The jigs are made with several identical board pieces and layers of cloth or Buckram. For example, the height jig is made of 2 board thicknesses plus 5 cloth thicknesses. The width jig consists of 1 board thickness plus 2 cloth thicknesses.

Once I have the bottom of the tray cut, I do the same for the three sides of the box.

Once I have the bottom of the tray cut, I do the same for the three sides of the box.

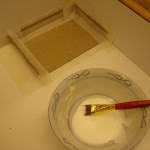

The next step is to line our box template with wax paper so the box that I am constructing will not stick to the template.

The next step is to line our box template with wax paper so the box that I am constructing will not stick to the template.

After doing that, I’ll glue the sides of the box to the bottom of the box with PVA adhesive. After checking to make sure that all pieces of the lower tray are fitting properly, I carefully stack several heavy lead weights inside the tray and let it dry thoroughly.

After doing that, I’ll glue the sides of the box to the bottom of the box with PVA adhesive. After checking to make sure that all pieces of the lower tray are fitting properly, I carefully stack several heavy lead weights inside the tray and let it dry thoroughly.

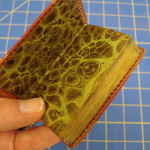

After drying, the lower tray is removed from the box template and inspected for fit and finish. Any rough areas are carefully sanded smooth. The tray is now ready to have the cloth covering attached.

After drying, the lower tray is removed from the box template and inspected for fit and finish. Any rough areas are carefully sanded smooth. The tray is now ready to have the cloth covering attached.

To cover the lower tray I first cut a strip of fabric that is the length of all three sides plus 1.5 inches. The width of the strip is two tray thicknesses plus 1.5 inches. The cloth is then carefully adhered to the tray with PVA one side at a time until all sides of the tray are covered.

To cover the lower tray I first cut a strip of fabric that is the length of all three sides plus 1.5 inches. The width of the strip is two tray thicknesses plus 1.5 inches. The cloth is then carefully adhered to the tray with PVA one side at a time until all sides of the tray are covered.

Next a specific series of cuts are made into the cloth with a scalpel. These allow the sides of the cloth to be folded and then glued to the tray without a lot of “bulk” showing.

When the lower tray has been completed, the upper tray is built around it, using the same steps that were used in the construction of the lower tray. Now is a good time to check the fit of the filler material to the lower tray.

When both trays are finished, paste downs are measured, cut and glued to the bottom of the trays. Wax paper and then several sheets of newsprint paper are placed over the paste downs and heavy weights placed on top and the trays are left to dry. The filler insert can now be glued into the lower tray with PVA adhesive.

When both trays are finished, paste downs are measured, cut and glued to the bottom of the trays. Wax paper and then several sheets of newsprint paper are placed over the paste downs and heavy weights placed on top and the trays are left to dry. The filler insert can now be glued into the lower tray with PVA adhesive.

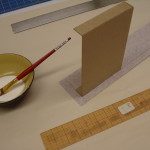

While this is drying, I can begin to make the cover for clamshell box. The cover consists of three pieces of the “70” board, a front, spine and rear cover. These pieces will be cut one or two board thicknesses larger than the upper tray and one thickness wider. Cloth material is selected and cut large enough so that there can be one inch turn-ins around all three boards. The boards are then placed on the cover cloth along a measured straight line.

While this is drying, I can begin to make the cover for clamshell box. The cover consists of three pieces of the “70” board, a front, spine and rear cover. These pieces will be cut one or two board thicknesses larger than the upper tray and one thickness wider. Cloth material is selected and cut large enough so that there can be one inch turn-ins around all three boards. The boards are then placed on the cover cloth along a measured straight line.

The joint jig is used to measure the joint distance between the spine board and the cover boards. Once the boards have been glued to the cloth, the corners of the turn-ins are clipped and the turn-ins are pasted down, over the boards. Finally, a strip of cloth is glued down between the boards and over the inner spine. The trays are now ready to be attached to the cover.

I’ll place the lower tray inside the upper tray and put both inside of the cover to check for fit and positioning. If the fit is correct, I carefully place the clamshell on my work space and open the cover. Next I’ll apply PVA to the bottom of the outer tray and close the cover over it, holding it in place for several seconds. After the cover and upper tray have set, I slowly open them and place heavy weights inside of the upper tray. I let the upper tray dry for a few minutes under weights, and then repeat this procedure with the lower tray. Finally, I put heavy weights in both trays and let them dry overnight.

I’ll place the lower tray inside the upper tray and put both inside of the cover to check for fit and positioning. If the fit is correct, I carefully place the clamshell on my work space and open the cover. Next I’ll apply PVA to the bottom of the outer tray and close the cover over it, holding it in place for several seconds. After the cover and upper tray have set, I slowly open them and place heavy weights inside of the upper tray. I let the upper tray dry for a few minutes under weights, and then repeat this procedure with the lower tray. Finally, I put heavy weights in both trays and let them dry overnight.

One of the last things I have to do before the box is complete is to stamp the book’s title with our hot stamper. I measure the thickness of the box to see how much room I’ll have for the title. If the thickness is an inch for example, I’ll have to choose a type size that will comfortably fit within that dimension. Because the book has a red cover with gold lettering, I’ll choose the same for the title. When the type has been selected and set, I’ll stamp the title using gold foil over red paper.

The title is then cut and trimmed to fit the spine of the clamshell. I will attach it with PVA mixture and put it under a weight to dry. The clamshell box is now completed.

The title is then cut and trimmed to fit the spine of the clamshell. I will attach it with PVA mixture and put it under a weight to dry. The clamshell box is now completed.

The final step in this assignment is to fill out the Book Conservation Worksheet. On this form I will record all of the things I’ve done in constructing the enclosure and the time it has taken to complete them (7.5 hours).

The final step in this assignment is to fill out the Book Conservation Worksheet. On this form I will record all of the things I’ve done in constructing the enclosure and the time it has taken to complete them (7.5 hours).

Patrick Schmude — Sr. Conservation Technician (UCL)